Vibro Shifter

Price 150000 INR/ Piece

Vibro Shifter Specification

- Type

- Batch Type

- Material

- SS 316, SS 304, Antistatic Halar Coating, Hastelloy C22

- Computerized

- No

- Automatic Grade

- Manual

- Control System

- Frequency Speed Control

- Drive Type

- Electric

- Voltage

- Machine to Machine Vary

- Power

- Machine to Machine Varry Horsepower (HP)

- Weight (kg)

- Machine to Machine Varry Kilograms (kg)

- Dimension (L*W*H)

- Machine to Machine Varry Millimeter (mm)

- Color

- SS

- Warranty

- 1 Year

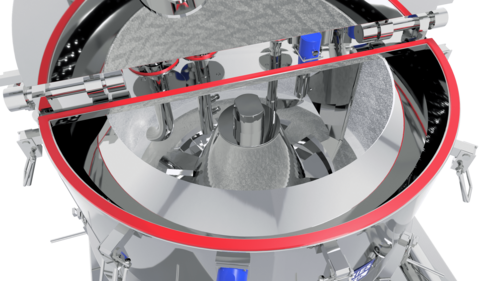

About Vibro Shifter

A Vibro Shifter, also known as a Vibro Sifter or Vibrating Sieve, is a mechanical device used to separate particles or materials based on their size and shape. It is commonly used in various industries, including pharmaceuticals, food processing, chemical, and cosmetic manufacturing. The primary function of a Vibro Shifter is to efficiently separate solids from solids or liquids from solids through vibration and sieving.

Here's how a Vibro Shifter typically works:

1. Basic Structure: A Vibro Shifter consists of a vibrating motor or an eccentric motor that generates vibrations. This motor is typically mounted on top of a sieve or screen.

2. Sieve or Screen: The vibrating motor imparts rapid vibrations to a sieve or screen mesh, causing it to shake or oscillate.

3. Material Loading: The material to be sifted is loaded onto the top of the sieve, often through a hopper or feeding mechanism.

4. Sieving Process: The vibration of the sieve or screen mesh causes the particles to move and separate based on their size. Smaller particles pass through the mesh, while larger particles are unable to pass through and are retained on the top surface.

5. Collection: The separated materials, such as fine particles or the desired product, pass through the mesh and are collected in a container or downstream process, while the oversize particles or impurities are collected separately.

Advantages of using a Vibro Shifter include:

1. Efficient Separation: Vibro Shifters are known for their efficient and rapid separation of particles, which is essential in industries where particle size control is crucial.

2. High Throughput: They can handle a large volume of material in a relatively short time, making them suitable for industrial-scale production.

3. Low Maintenance: They are typically low-maintenance machines with simple mechanical components.

4. Customization: Vibro Shifters can be customized with different mesh sizes to suit specific particle size separation requirements.

5. Hygienic Design: In industries like pharmaceuticals and food processing, Vibro Shifters are designed to meet strict hygiene and safety standards.

6. Reduced Noise and Dust: They are generally quieter than some other sieving methods and can help reduce dust emissions.

Applications of Vibro Shifter:

1. Pharmaceutical Industry:

a. Pharmaceutical Powders: Vibro Shifters are used to separate and classify pharmaceutical powders, ensuring that they meet the required particle size specifications for drug formulation.

b. Tablet Coating: They are employed in tablet coating processes to remove oversize or undersize particles, ensuring uniform coating.

2. Food Processing:

a. Flour and Starch: Vibro Shifters are used to sift flour, starch, and other food ingredients to remove impurities and achieve consistent particle size for baking and food production.

b. Spices and Seasonings: In the spice industry, they help remove foreign particles and ensure a uniform particle size for spice blends.

c. Dairy Products: Vibro Shifters are used to sift milk powder, whey, and other dairy ingredients for various dairy product applications.

3. Chemical Industry:

a. Chemical Powders: Vibro Shifters are employed in the chemical industry to classify and separate various chemical powders, ensuring product quality and consistency.

b. Paints and Coatings: They help ensure the uniformity of particle size in paints, coatings, and pigments.

4. Cosmetic Industry:

a. Cosmetic Powders: Vibro Shifters are used to sift cosmetic powders such as talc, pigments, and additives to achieve the desired particle size and consistency in cosmetic products.

b. Face and Body Scrubs: In the production of exfoliating scrubs, they help remove oversized abrasive particles.

5. Mining and Metallurgy:

a. Mineral Processing: Vibro Shifters are used in mineral processing plants to separate and classify minerals and ores based on particle size.

b. Metal Powder Production: They are used to sift metal powders for various metallurgical applications.

6. Plastics and Polymers:

a. Plastic Granules: In plastic manufacturing, Vibro Shifters are used to classify and separate plastic granules, ensuring uniformity and quality in the final products.

7. Recycling:

a. Recycling Plants: Vibro Shifters are utilized in recycling facilities to separate different-sized particles of recycled materials, such as plastic, paper, and glass.

8. Agriculture:

a. Seed Sorting: In seed processing plants, Vibro Shifters help separate seeds based on size, ensuring uniformity and quality in seed batches.

9. Environmental Remediation:

a. Soil Remediation: Vibro Shifters can be used to sift contaminated soil, separating pollutants from clean soil in environmental cleanup efforts.

10. Construction Materials:

a. Aggregate Production: In the production of concrete and construction materials, they are used to classify and separate aggregates like sand, gravel, and crushed stone.

FAQ:

Q. What is a Vibro Shifter?

Ans: A Vibro Shifter, also known as a vibrating sifter or vibratory sieve, is a mechanical device used to separate particles or materials based on their size and shape through vibration and sieving.

Q. What are the main components of a Vibro Shifter?

Ans: The main components typically include a vibrating motor or eccentric motor, a sieve or screen mesh, and a housing or frame.

Q. How does a Vibro Shifter work?

Ans: A Vibro Shifter works by generating rapid vibrations with a motor, causing the sieve or screen mesh to shake. This motion separates particles based on their size, with smaller particles passing through the mesh and larger particles being retained on the top surface.

Q. What industries use Vibro Shifters?

Ans: Vibro Shifters are used in a wide range of industries, including pharmaceuticals, food processing, chemical manufacturing, cosmetics, mining, agriculture, and recycling, among others.

Q. What are the advantages of using a Vibro Shifter?

Ans: Advantages include efficient particle separation, high throughput, low maintenance, customization with different mesh sizes, hygienic design for industries like pharmaceuticals and food processing, and reduced noise and dust emissions.

Q. What types of materials can be processed with Vibro Shifters?

Ans: Vibro Shifters can process various materials, including powders, granules, particles, seeds, minerals, and more, depending on the specific application and mesh size used.

Q. How do you select the right mesh size for a Vibro Shifter?

Ans: The mesh size should be selected based on the desired particle size separation and the characteristics of the material being processed. It often requires testing to determine the appropriate mesh size.

Q. Are Vibro Shifters easy to clean and maintain?

Ans: Yes, Vibro Shifters are generally low-maintenance machines with simple mechanical components. They are designed for easy cleaning and sanitation, particularly in industries with strict hygiene requirements.

Q. Can Vibro Shifters be customized for specific applications?

Ans: Yes, Vibro Shifters can be customized with different mesh sizes, materials, and configurations to suit specific particle size separation requirements and industry standards.

Q. Are there safety precautions to consider when operating a Vibro Shifter?

Ans: Yes, operators should follow safety guidelines when operating Vibro Shifters, including wearing appropriate protective gear, ensuring the machine is properly secured, and disconnecting power before maintenance.

Q. What is the typical capacity of a Vibro Shifter?

Ans: The capacity of a Vibro Shifter can vary widely depending on its size and design. They are available in various capacities to suit different production requirements.

Q. Can Vibro Shifters be used for wet materials?

Ans: Some Vibro Shifters are designed for wet sieving applications and can handle materials in liquid form. These are often used in industries like pharmaceuticals and ceramics.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machinery Category

Mass Mixer

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Material : SS 316, SS 304, Antistatic Halar Coating, Hastelloy C22

Color : SS

Automatic Grade : SemiAutomatic

Multi Point Full Body Bottom Cake Discharge

Price 25000000 INR / Set

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Material : SS 316, SS 304, Antistatic Halar Coating, Hastelloy C22

Color : SS

Automatic Grade : Automatic

GST : 27AAICA7458F1ZG

|

Ace Industries (India) Private Limited

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry